Rules that came into force in April 2018 mean more bike kit than ever before has CE safety approval. Here’s SBS Mag’s guide to what it all means.

There’s been a CE standard for bike clothing since 2002 - and before that there was an independent test specification called the Cambridge Standard - but manufacturers weren’t obliged to submit their items for testing. The only kit that needed testing by law was body armour (and helmets, but they come under a different regulation).

Some manufacturers did have their kit approved, especially those making boots and (more recently) gloves. But most didn’t, and hardly any jackets, jeans or suits were CE-approved.

Then came April 2018’s law change, which designated all motorcycle clothing imported to Europe and the UK as Personal Protective Equipment that is required to prove it’s up to muster by passing independent tests.

Kit imported into Europe before that date can still be sold legally, but nothing new can be legally brought in unless it has been independently tested and certified as the legislation demands.

Since April 2018 the number of CE-approved jackets, jeans and suits has been steadily increasing, and in Post-Brexit Britain we're also seeing the 'UKCA' mark alongside the CE logo on bike kit. At the moment, the same standards are used for both CE and UKCA.

Manufacturers can still test to the previous CE standard (EN 13595), but this is due to be de-listed in September 2022. Now, most clothing meets the new standard - EN 17092. It’s less stringent than the old one and means the lighter clothing many riders demand can be approved to a CE standard.

In EN 17092 clothing is tested to make sure it resists abrasion on a road surface, that seams are strong enough to stay together in a spill and the material itself won’t tear apart. In addition, where body armour is required to be fitted it must pass separate impact tests that have been around since 1995 (with subsequent updates).

There are three main pass levels within EN 17092 – the highest is AAA and the lowest is A. There are additional B and C ratings, which we’ll deal with later.

For those who want more detail, here’s how jackets, jeans and suits are tested to EN 17092…

In the zone…

The body is divided into three areas depending on the likelihood of them hitting the ground in a crash. Zone one covers the most vulnerable areas of the body and zone three covers the parts least likely to hit the ground first.

The garment is then tested in the following ways…

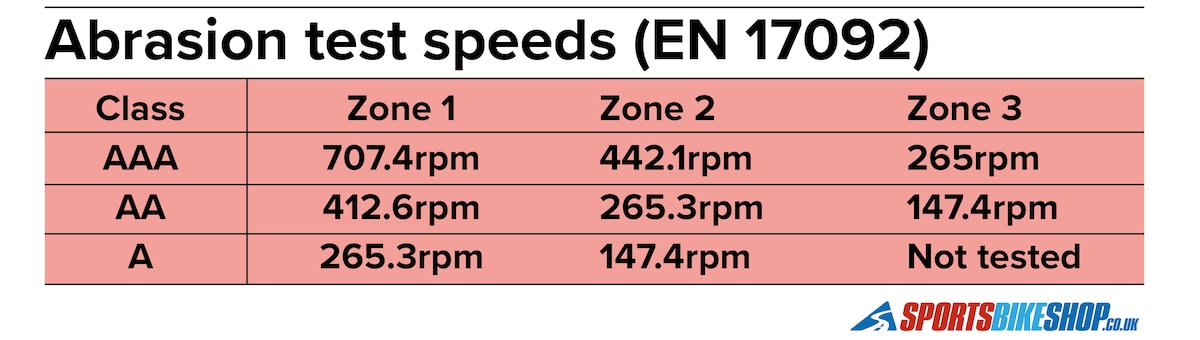

Abrasion resistance

A sample is cut from the clothing and installed into a device known as a Darmstadt machine. This machine spins the sample at a prescribed rpm then drops it onto a concrete slab and allows it to slow to a stop. To pass, any holes in the garment sample need to be less than 5mm wide. The speed at which the sample spins before being dropped dictates the level of pass, from AAA down to A. Our graphic below shows how spin speed is turned into an approval rating.

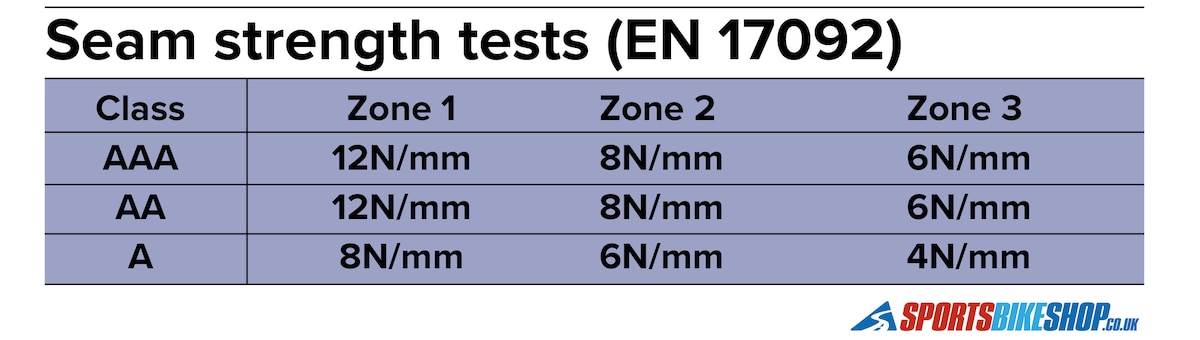

Seam strength

A sample is cut from the garment and clamped between two pairs of jaws, one pair on each side of the seam. The two sets of jaws are pulled apart at a force dictated by the level of test being conducted. If the seam comes apart under the strain, the garment fails the test. Our graphic shows the forces a seam needs to survive to reach the different pass levels, depending on where it’s located on the garment.

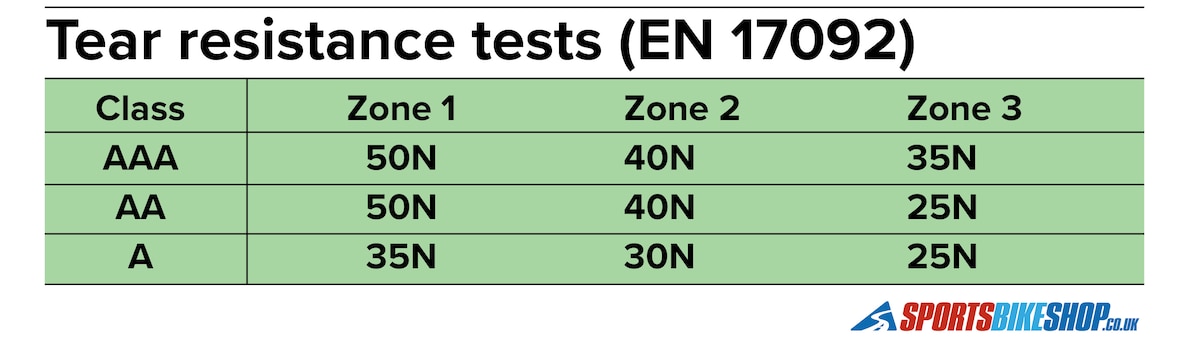

Tear strength

Another sample from the garment is clamped between two pairs of jaws, which are then moved apart at a set rate until the sample either comes apart or meets the minimum requirement for the test being carried out. Our graphic shows how tough the material has to be to pass the various levels.

How the overall ratings are reached…

Nine individual abrasion tests are conducted, while the number of seam and tear strength tests carried out depends on how many different types of seams are used in a garment and what material is used.

The overall performance classification achieved by the garment is offset by the lowest achieved in any one of the individual tests. So if a garment scores AAA in all but one of the individual tests, then only reaches A in the other test, it will only be rated as an overall pass at A.

And there’s more…

As well as the AAA, AA and A ratings explained in our graphics, there are additional ratings of B and C.

If you see clothing with a B-rating, this means it has no armour, but passes the abrasion, seam and tear tests to the same level as an A-rated garment.

The C rating is for armoured shirts, with different tests depending on whether they are designed to be worn next to the skin or as an outer layer. If you see something marked as 'CU' it is approved for use with an abrasion-resistant outer garment. If it's marked 'CO' then it has also passed the abrasion part of the CE test.

And finally... Class categories

You may see the CE standard expressed as EN 17092 with a digit afterwards. This will tell you which part of the standard it approved to.

EN 17092:1 Overall test methods (you shouldn't see this on a garment label)

EN 17092:2 Pass at AAA

EN 17092:3: Pass at AA

EN 17092:4: Pass at A

EN 17092:5: Pass at B

EN 17092:6 Pass at C